Bata usage of MINZ Energy Saving System

MINZ Servo Energy Saving System is a modern automated system that incorporates closed-loop feedback for motion control. A servo system consists of servo motor, internal gear pump, motor driver and feedback elements combined in a manner that gives accurate and stable control over speed and position.

Closed-loop pressure and flow controller perfectly transmits command and real value of a machine’s different motions. MINZ’s patented servo system automatically sends commands to servo motors to output accurate motor turning speed according to your machine’s hydraulic design. When servo motors run at proper rotary speed, there is no energy wastage. Using internal gear pump, big pressure can be achieved with little motor turning speed, thus saves electricity comparing to traditional power system.

So far, MINZ Servo Energy Saving System has been installed in Bata Group’s Asia & Africa factories. Electricity usage for these injection machines have been lowered more than half! Heat generated from hydraulic fluid has been lowered as well, and chiller for water can be turned down to save extra energy. And because motors are not 100% turning, a quieter and friendlier working environment is achieved. Furthermore, higher precision of mechanism motions can reduce shoe defects due to instant feedback & correction.

A grown up tree can consume 465kg of CO², and to generate 1 kwh exhausts 0.75kg of CO². Taiwan’s biggest park is DaAn National Park, it has 20,745 trees. So far, Bata Group has helped the world to create 8 DaAn National Park by using servo systems to save 5,000,000 kwh per year, which is a honorable green saving practice.

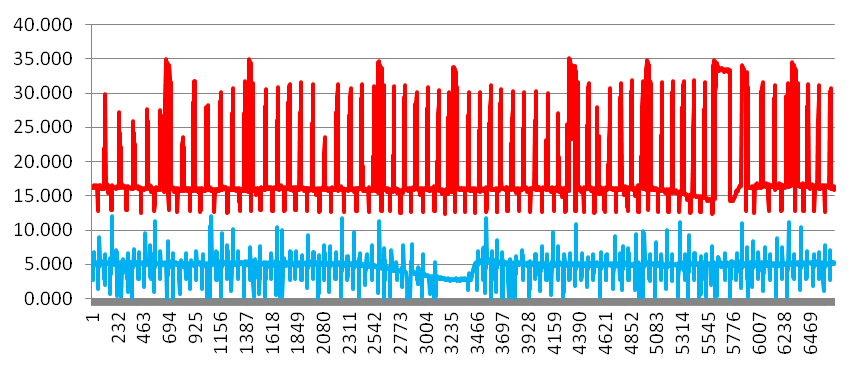

1. Energy-saving comparison:

(1)Rotary Injection Machine:

| 30 min. total KWH | 30 min. average KW | Energy Saving | |

|---|---|---|---|

| Before | 8.9KWH | 17.91KW | 0% |

| After | 2.4KWH | 4.69KW | 73% |

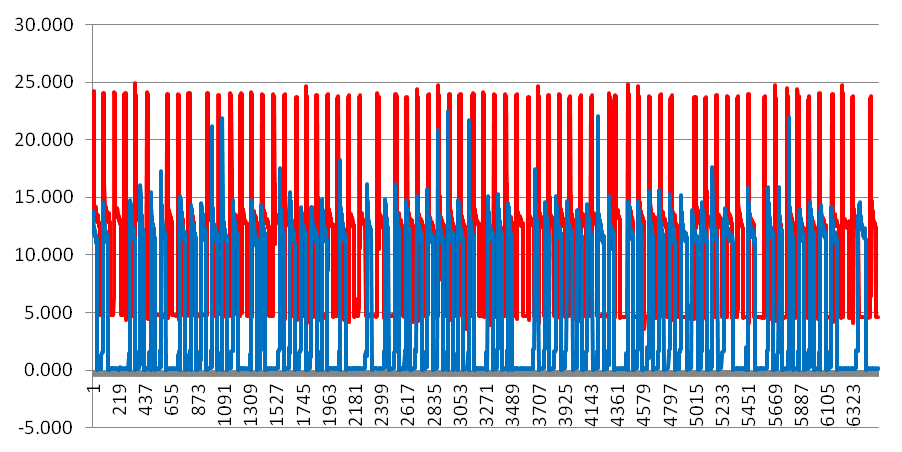

(2)DIP Injection Machine:

| 30 min. total KWH | 30 min. Average KW | Energy Saving | |

|---|---|---|---|

| Before | 9.8KWH | 19.53KW | 0% |

| After | 3.4KWH | 7.02KW | 65% |

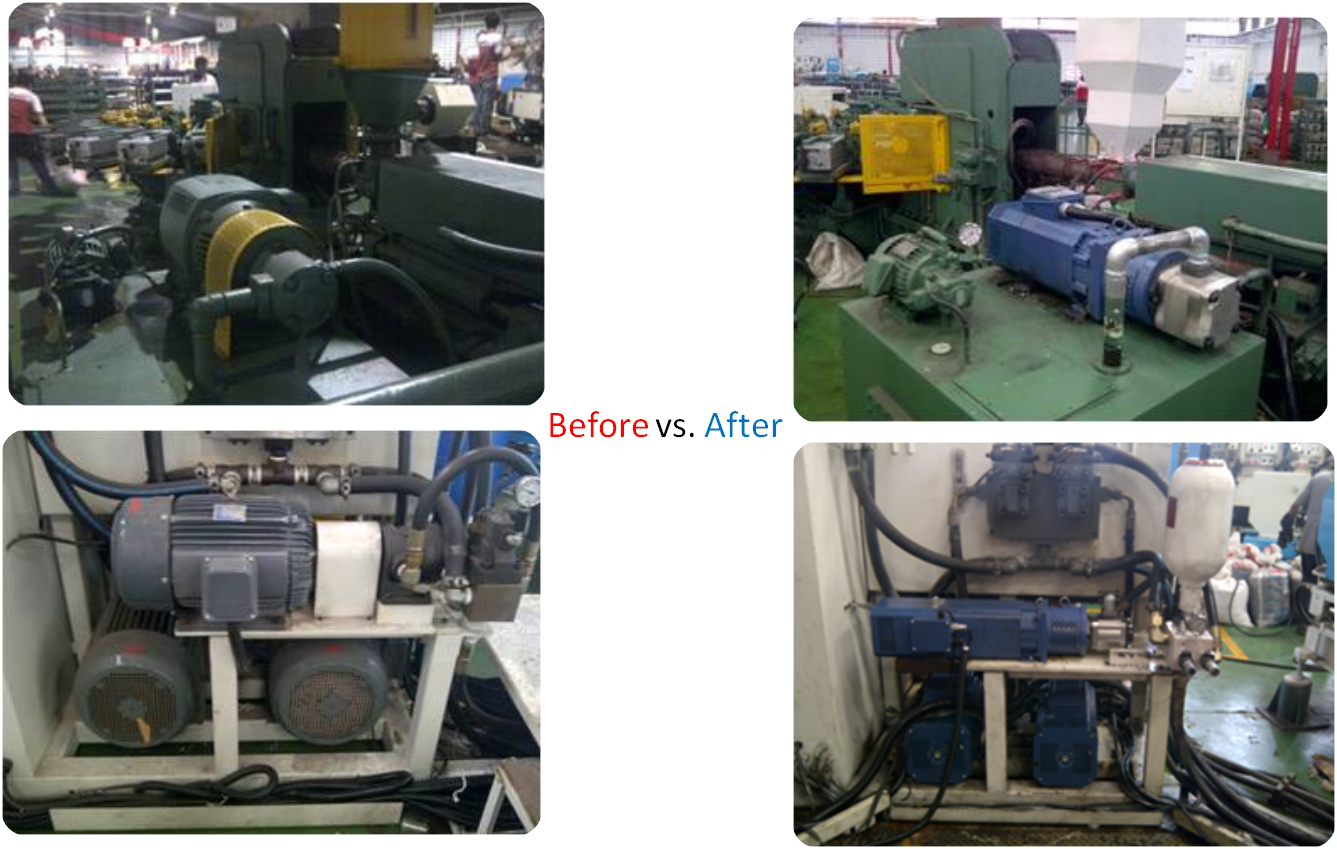

2. Pictures comparison: